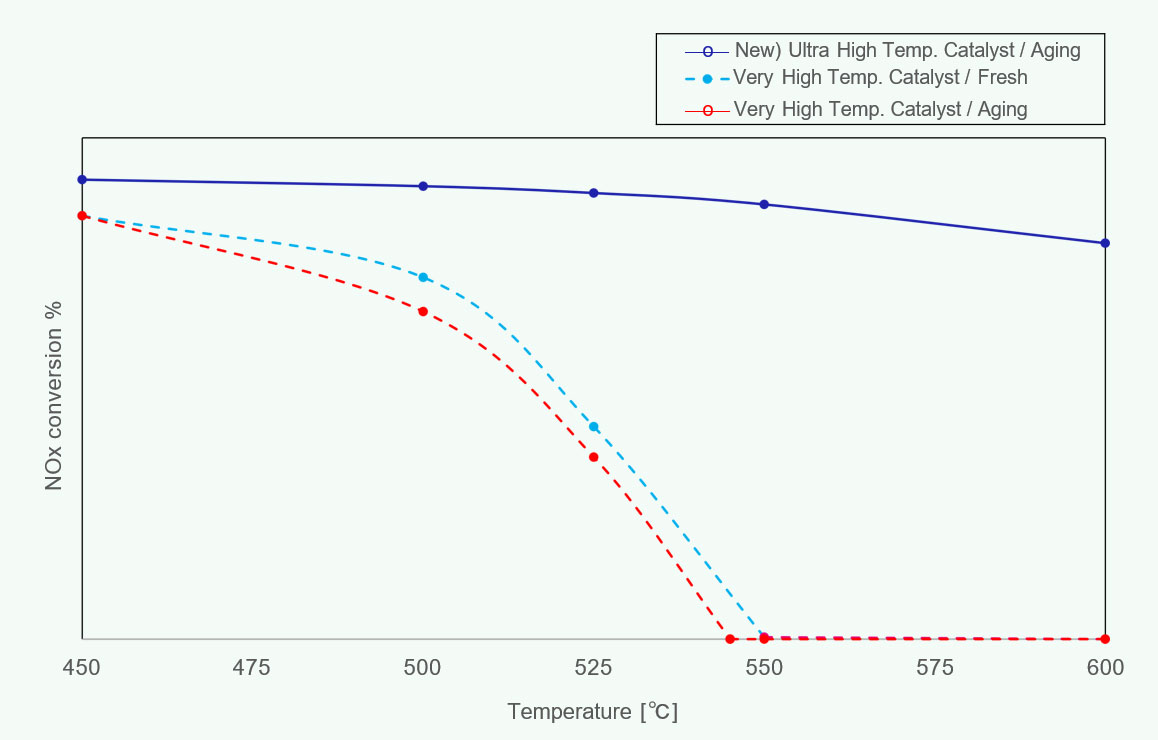

A catalyst is a substance that speeds up a chemical reaction, or lowers the temperature or pressure needed to start one, without itself being consumed during the reaction. Catalysis is the process of adding a catalyst to facilitate a reaction. Using catalysts leads to faster, more energy-efficient chemical reactions.

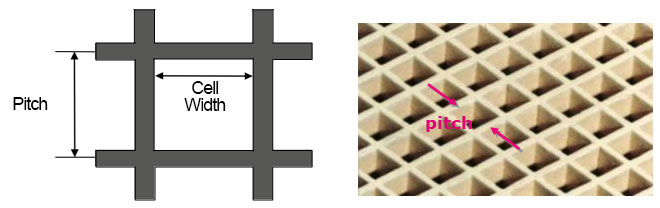

Several pitches for applications such as WtE and engine, etc.

For high dust applications e.g. coal fired power plants

Owner/Operator:

DONG Energy A/S

Rating:

800 MWt

Fuel:

Wood pellets

Catalyst reload:

2011 – 2013

NOx emission target:

< 150 mg/Nm3

Ammonia slip:

< 5 ppm

Catalyst Data:

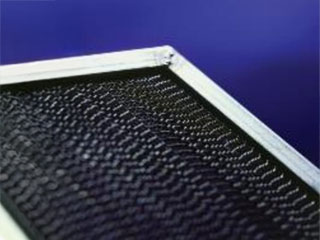

SINOx® plate-type

Owner/Operator:

GDF Suez

Rating:

447 MWt

Fuel:

Wood chips + Agro mixture

SCR first start-up:

2012

NOx Reduction:

> 30%

Ammonia slip:

< 5 ppm

For removal of odor and volatile compounds

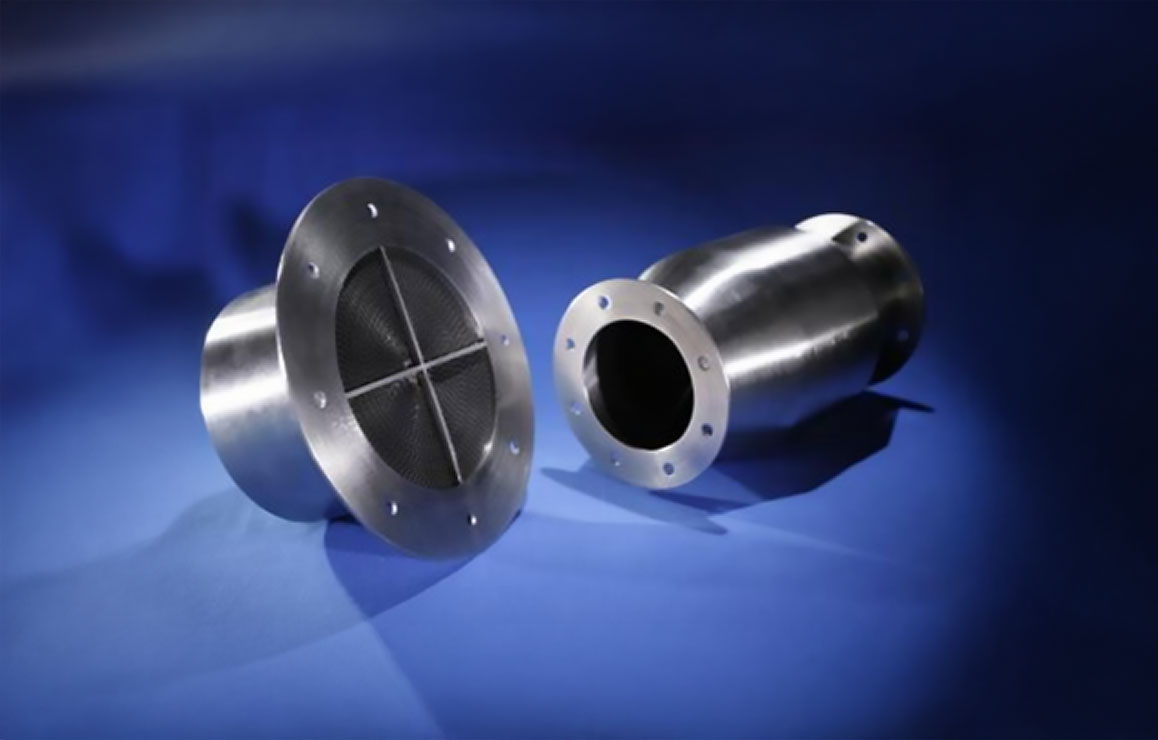

High PM reduction for use with Diesel engines >1kw – >1,000kW

Arrange a converstion with our expert.