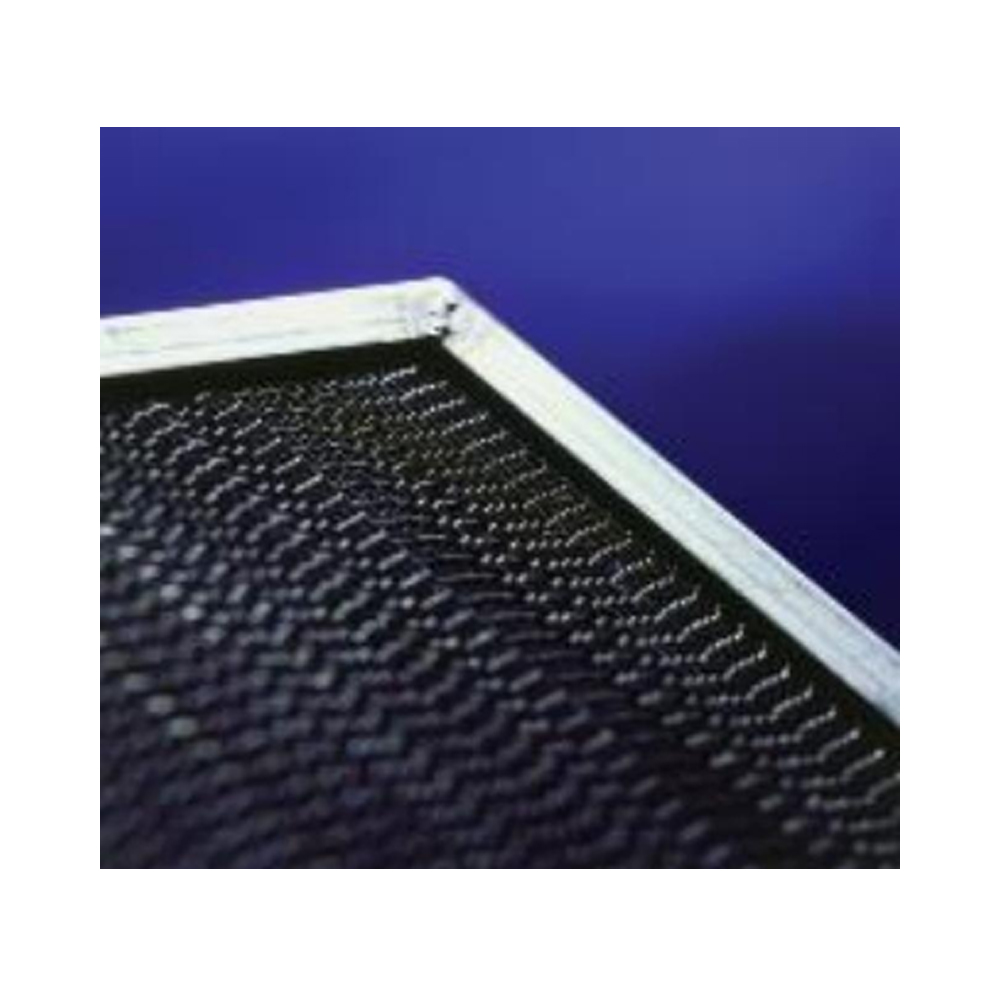

Oxidation Catalysts

For removal of odor and volatile compounds

- CO, VOC, HC Oxidation

- Gas and Diesel engines

- Gas turbines

- Typically 100-200-300 cells / in2

- Custom Block Sizes Round max. : Φ950mm Rectangle max. : 762 x 609mm Depth: 38-150mm

- Fully Brazed for Strength

- Thin walls for Low Pressure Drop

- Economical Formulations

- Easy Reload of other Designs

For removal of odor and volatile compounds

- CO, VOC, HC Oxidation

- Gas and Diesel engines

- Gas turbines

- Typically 100-200-300 cells / in2

- Custom Block Sizes

Round max. : Φ950mm

Rectangle max. : 762 x 609mm

Depth: 38-150mm - Fully Brazed for Strength

- Thin walls for Low Pressure Drop

- Economical Formulations

- Easy Reload of other Designs

Loading...

Description

Catalyst Design Factors

Application / Process

- Exhaust Gas Composition (CO, VOC, O2, H2O)

- Flow Rate, Temperature, Pressure

- Catalyst Contaminants

- Required Destruction Efficiency

- Constraints

- Pressure Drop, Space

- Maintenance Interval

- Durability

- Economical Constraints

- Target Costs, PGM-Loading, PGM-Prices